This difference underlines the dynamic mother nature of cleanroom environments and the necessity for rigorous checking and Regulate processes.

It is mostly recognized that if fewer particulates are existing in an operational clean room or other controlled natural environment, the microbial count less than operational situations are going to be fewer, supplied there are no improvements in airflow, temperature, and humidity. Clean rooms are managed under a point out of operational Management on The premise of dynamic (operational) information.

This Web page is employing a safety support to guard itself from on the net assaults. The action you just performed activated the security Remedy. There are various steps that would induce this block like submitting a particular word or phrase, a SQL command or malformed info.

Lastly, the analytical electric power may be enormously decreased by dilution from the contaminate. Because of this sort of difficulties, rinse and/or swab samples need to be made use of along side the placebo strategy.

1. Air provided through HEPA filters with superior air changes to dilute and take away the particles and microbial contamination created by personnel as well as equipment.

Craze Evaluation—Facts from the program microbial environmental checking plan which can be connected with time, change, facility, etc. This info is periodically evaluated to ascertain the standing or pattern of that program to ascertain whether it's underneath ample Handle.

Considering that the geometry of the container (dimensions and opening from the container) plus the speed of the line are components which are variable in the use of an get more info aseptic processing line, appropriate mix of these elements, if possible on the extremes, ought to be Utilized in the qualification of the line. A rationale for items employed must be documented.

To be able to start a fireplace a few elements are necessary, and these are usually represented as the sides of a fire triangle. A fire is usually extinguished by eradicating any one of several 3 factors revealed in the hearth triangle.

Air Velocity Examination: This entails measuring the pace of air movement within the cleanroom. Right air velocity is important for guaranteeing that particulates are successfully removed and that there's a uniform distribution of filtered air across the room.

Establish the number of cleaning procedures for each bit of apparatus. Ideally, a chunk of apparatus or program may have one particular process get more info for cleaning, however this will rely upon the goods getting developed and whether or not the cleanup takes place among batches of a similar product or service (as in a considerable campaign) or between batches of various goods.

A sample of your placebo batch is then tested for residual contamination. On the other hand, we have documented numerous important concerns that must be dealt with when utilizing placebo item to validate cleaning processes.

The area getting controlled airborne particle concentration is regarded as the clean zone or clean room. These areas are manufactured to minimize the introduction, technology, and retention of airborne particles while in the area.

Having said that, an investigation ought to be implemented and an evaluation of the possible impact this has on a product really should be created.

Article-occupancy, the focus shifts toward protecting the cleanroom’s general performance and setting up for foreseeable future recommissioning, underscoring the ongoing mother nature of cleanroom administration and optimization.

Taran Noah Smith Then & Now!

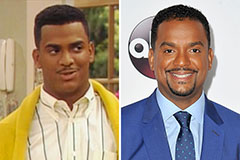

Taran Noah Smith Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Jane Carrey Then & Now!

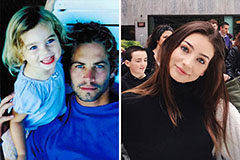

Jane Carrey Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!